Classification of Hydropower Plants

a) Based on Purpose

1. Single Purpose Project

It is solely designed for the purpose of hydroelectricity generation.

Eg: Upper Tamakoshi Hydropower Project

Khimti Khola Hydropower Project

2. Multipurpose Project

It is designed to fulfill more than one function or objectives. For example, the water diverted for hydroelectricity generation may also be utilized for irrigation purpose.

Eg: Bheri Babai Diversion Multipurpose Project

Sunkoshi Marin Diversion Multipurpose Project

b) Based on Operation

1. Isolated Plant

Micro and mini hydropower plants in rural areas may be designed to serve particular village only and is not connected to the national grid is called isloated plant.

2. Grid Connected Plant

Hydropower plant with a power station feeding to a grid is called grid connected plant.

c) Based on Head

According to Dandaker and Sharma, hydropower plants can be categorized based on head as below:

Low head plants: <15m

Medium head plants: 15 - 70m

High head plants: 71 - 250m

Very high head plants: >250m

In case of Nepal, the following classification can be adopted:

Very high head plant: >350m

High head plant: 150 - 350m

Medium head plant: 60 - 150m

Low head plant: Below 60m

Very low head plant: Upto 15m

d) Based on Plant Capacity

As per Dandaker and Sharma, hydropower plants can be categorized based on capacity as below:

Micro hydel plants: <5 MW

Medium capacity plants: 5 - 100 MW

High capacity plants: 101 - 1000 MW

Super plants: >1000 MW

In case of Nepal, the following classification can be adopted:

Micro plants: upto 100 KW

Mini plants: 100 - 1000 KW

Small plants: 1 - 25 MW

Medium plants: 25 - 100 MW

Large plants: >100 MW

e) Based on Storage Capacity

1. Run of River (ROR) Project

Those plants which do not regulate the hydrograph of source river in seasonal term, are known as ROR plants. Such plants are located in perennial river. Weir is constructed across the river to maintain the required water level u/s of weir and water is diverted into a waterway. It may have following three possible layouts:

- ROR project with canal system

- ROR project with pipe option

- ROR project with tunnel option

Keeping the considerations during peak hours, ROR plants may be constructed with pondage, which can regulate daily hydrograph or weekly hydrograph and store water (full or partial) to run the plant under full capacity is called PROR plant.

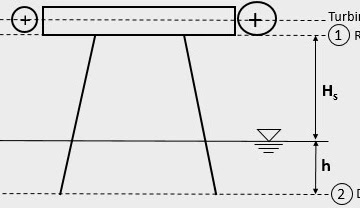

Fig: General Layout of ROR type hydropower project

2. Storage Project

Those plants which can regulate the hydrograph of river by one or more seasons, are usually known as storage plants. Such plants are located in non-perennial rivers. A dam is constructed across the river that creates a large reservoir in front of it. It may be of following types:

- Storage project with powerhouse at dam toe

- Storage project with powerhouse at certain distance d/s of dam

The storage project may be of seasonal storage, annual storage, and pumped storage based on regulation of water. Pumped storage plants use excess electricity during periods of low demand to pump water from a lower reservoir to an upper reservoir. Then, during periods of high electricity demand, the stored water is released from the upper reservoir to the lower reservoir, generating electricity in the process.